Hanover Fair: GKN Hydrogen presents the world's safest hydrogen storage solution for industrial applications

Power-to-gas (P2G) solutions for the decarbonization of of industrial infrastructures and utilities

Electric power generation through the use of hydrogen gas engines

Resilience of energy backup systems using hydrogen storage in metal hydride

Hall 13/Booth B35

GKN Hydrogen, technology leader for safe and compact storage of hydrogen in metal hydrides, is presenting its industrial solutions for the first time at the Hanover Fair from April 22nd to 26th in Hanover. The globally active company will be demonstrating how users can commercially utilize safe and compact hydrogen storage solutions for the decarbonization of their processes. As part of the Hydrogen + Fuel Cells EUROPE Community, the company will be showcasing current and future applications with metal hydride storage systems in Hall 13/Booth B35.

With its focus on storage for green hydrogen in solid form (metal hydride), GKN Hydrogen presents itself as a pioneer in safety and efficiency for the industry. GKN Hydrogen offers safe storage systems for green hydrogen worldwide and is concentrating on two main topics in Hanover: industrial P2G solutions and hydrogen gas engines.

Under the topic of industrial P2G solutions, aspects such as hydrogen-gas mixtures, green steel and ammonia production, petroleum refining and industrial heating will be highlighted.

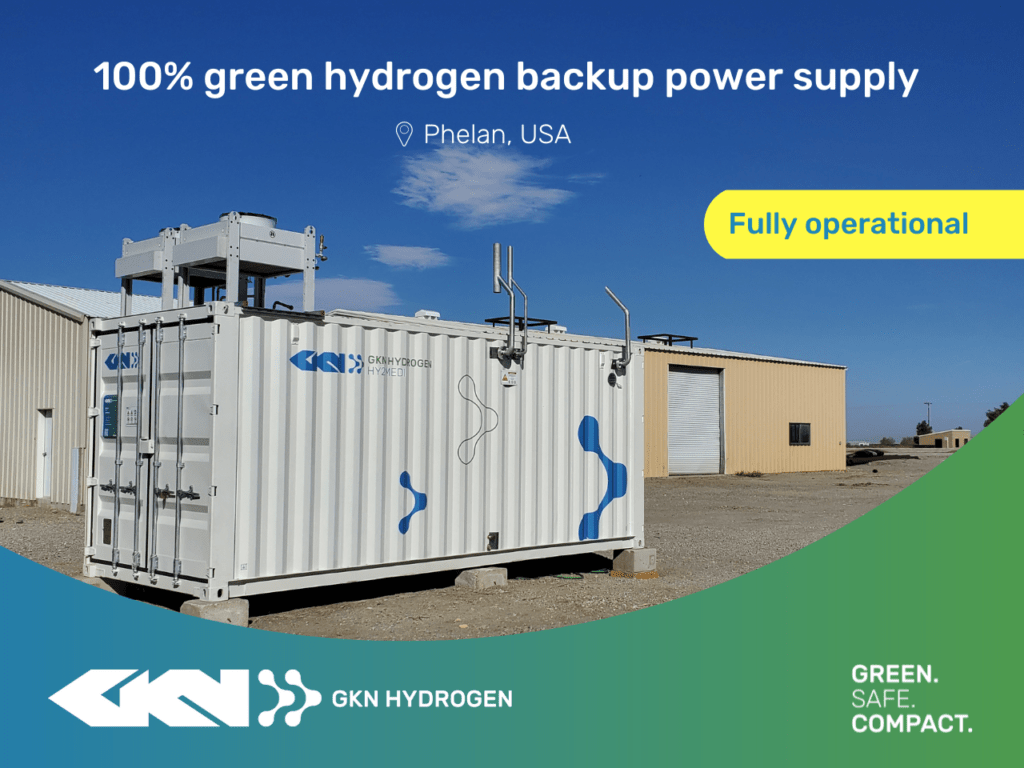

The topic of hydrogen gas engines includes backup solutions for critical infrastructures such as data centers, hospitals, and telecommunications systems, as well as transportable energy generation on construction sites and combined heat and power plants.

A visit to GKN Hydrogen in Hall 13/Booth B35 will be worthwhile:

Download press release:

About GKN Hydrogen

GKN Hydrogen is pioneering safe, zero-emission storage of green hydrogen, helping users and organizations around the world achieve their environmental and carbon neutrality goals today and in the years to come. The company develops and markets systems and solutions for the use of green, electrical energy and hydrogen. The systems generate green hydrogen from renewable energy sources and store it compactly and loss-

free in metal hydride over long periods of time. Depending on requirements, the green

hydrogen can be used directly or converted back into electricity and heat. GKN Hydrogen is part of Dowlais, an engineering group specializing in the automotive sector.

Contact GKN Hydrogen

Dirk Bolz – Director Sales & Marketing